At CISFA, studies are carried out on drone structures on both a macroscopic and microscopic scale, using specific simulation techniques.

The structural analyzes are carried out in order to be able to equip the drones with specific sensors and measuring instruments capable of detecting the presence of volcanic ash, SO2, CO2 and other pollutants in the atmosphere, following paroxysmal events. In particular, by modeling the tubular structure of the drone with a sandwich composed of polystyrene core, carbon fiber skins and epoxy matrix, it is possible to achieve weight savings compared to standard commercial drones.

Furthermore, the molecular structure of polystyrene chains is studied using Molecular Dynamics simulations, providing further information on the local structure of polymer chains.

The mechanical design of lightweight structures allows us to obtain, through topological and material optimization, a lighter and more efficient structure, capable of maintaining the same mechanical performances of the original material and, in some cases, improving them.Over the past fifty years, composite materials such as carbon fiber or Kevlar have supplanted the use of metals, such as aluminum, in the construction of cockpits in various competitive sports, as well as in the automotive and offshore industries.

Over the past decade, many advances have been made in additive manufacturing (AM), and thanks to topology optimization techniques, lightweight structures can be produced quickly and efficiently.

A very popular application of this technology is drones which can be used in a wide variety of contexts; from simple entertainment to monitoring weather conditions and pollutants in the atmosphere.One of the constituent elements of drones that requires great care during assembly is the frame. The latter, in fact, must be able to withstand the great stress to which the drone is usually subjected during the flight phase. The frame of a drone is typically made of a plastic, aluminum and carbon support.

The behavior of the plastic material, in particular, is fundamental to giving the necessary flexibility to the frame; at the same time it must be sufficiently resistant to avoid breakages as well as acting as a thermal and electrical insulator. In this regard, to understand the microscopic behavior of the plastic materials that make up the frame of the drone, specific investigation techniques were used, such as Molecular Dynamics (MD) simulations or X-ray scattering, widely used to study the fluid structure of polymers and block copolymers.

The MD technique has been widely adopted to perform simulation studies of both melted polystyrene and composite materials obtained by filling the polymer matrix with inorganic particles or nanotubes; the use of MD techniques allows to acquire knowledge on the structural and dynamic properties of the polymer chains, which, in turn, determine the final properties of the material. In particular, it is possible to estimate chain relaxation, the time necessary for a polymer chain to assume its equilibrium configuration, which strictly depends on the temperature, density and interactions with the other chains and with the solvent. Furthermore, the calculation of end-to-end distance, radius of gyration, chain orientation and density profiles provides an overall picture of the microscopic properties of the material.

As regards finite element simulations, case studies relating to commercial drones, such as the DJI S900 model, were covered. In this regard, techniques have been implemented to lighten the load-bearing structure, while at the same time leaving the mechanical characteristics unchanged, obtaining greater battery autonomy and, consequently, greater flight autonomy.

The DJI S900 is a hexacopter equipped with six arms that support the six rotors; main features include a maximum motor power of 500 watts, a total weight (including batteries) of 3.3 kg and a take-off weight of approximately 8 kg.

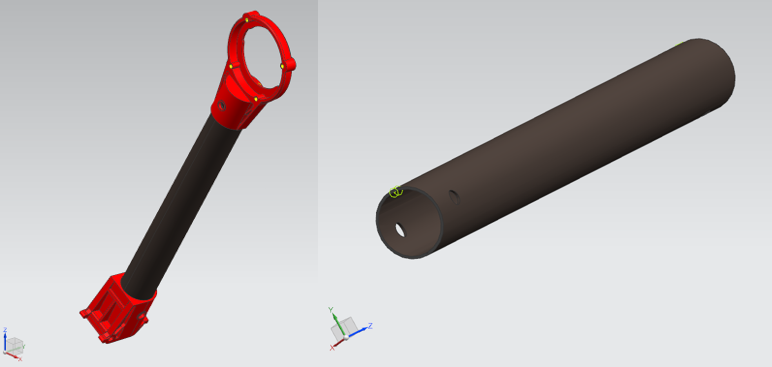

The tubular laminate of the drone arm (1 mm thick) is made of carbon fiber; the fixing of the rotor and the anchoring of the arm to the body of the drone is made of aluminium; the body of the drone for housing the electronic controls is made of plastic materials. The reverse engineering of the drone is shown in the following figure.

In a recently published paper (DOI: 10.1478/AAPP.99S1A33), the simulation and creation of a drone was discussed in which the laminate of the supporting structure of the rotors (consisting only of carbon fiber and epoxy resin) was replaced with a sandwich consisting of a polystyrene core (center) and a carbon fiber and epoxy skin, resulting in a weight saving of 7 grams for each drone arm compared to standard commercial drones.